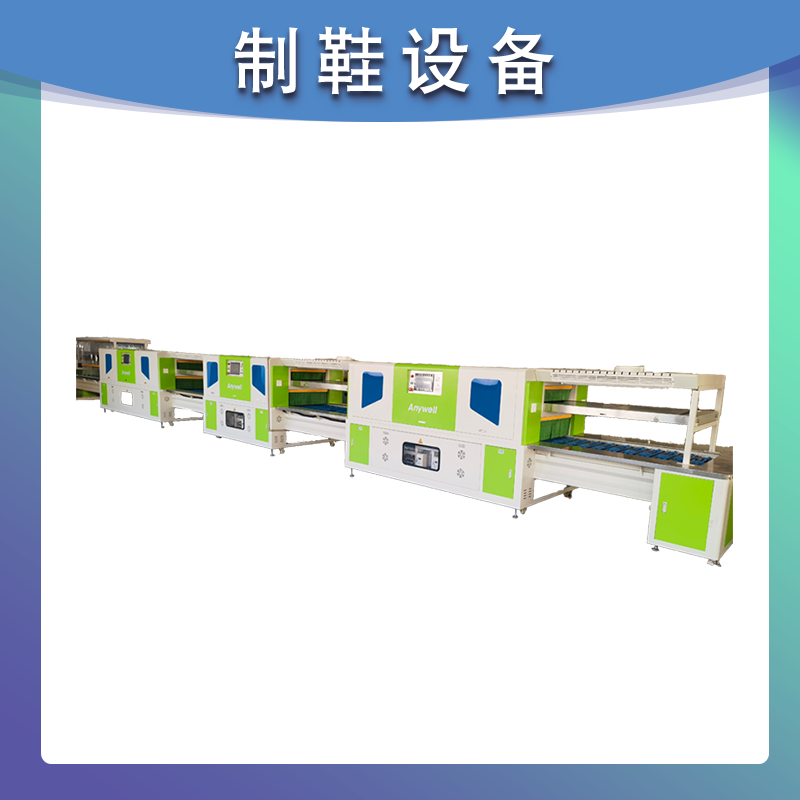

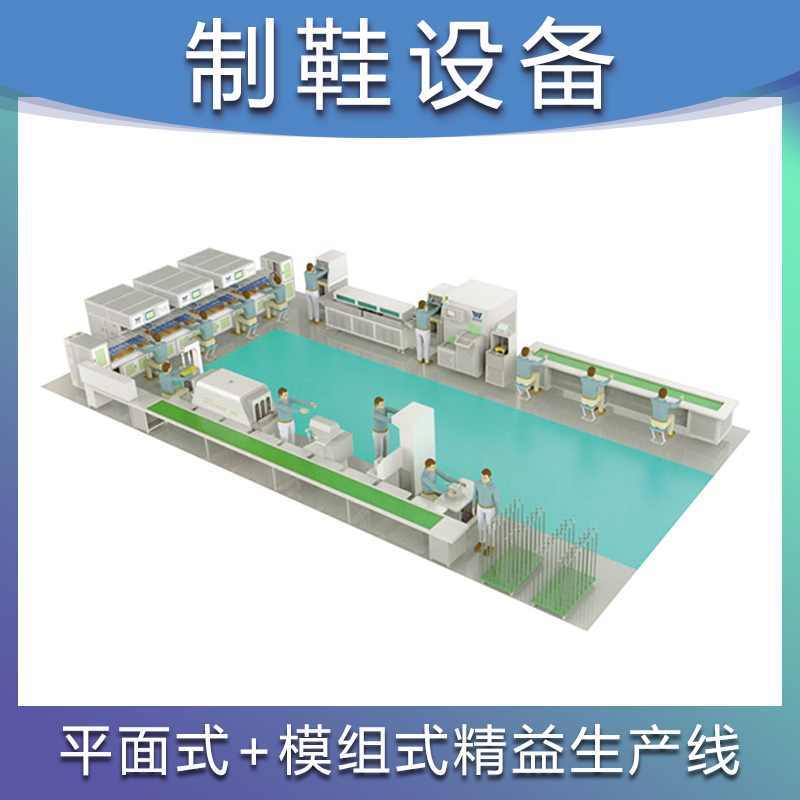

流水线特性:

1. 高效生产:多工位协同作业,实现产品连续加工,生产效率提升50%以上,大幅缩短交货周期。

2. 精准分工:标准化作业流程,各环节专人专岗,降低人为误差,保障产品品质一致性。

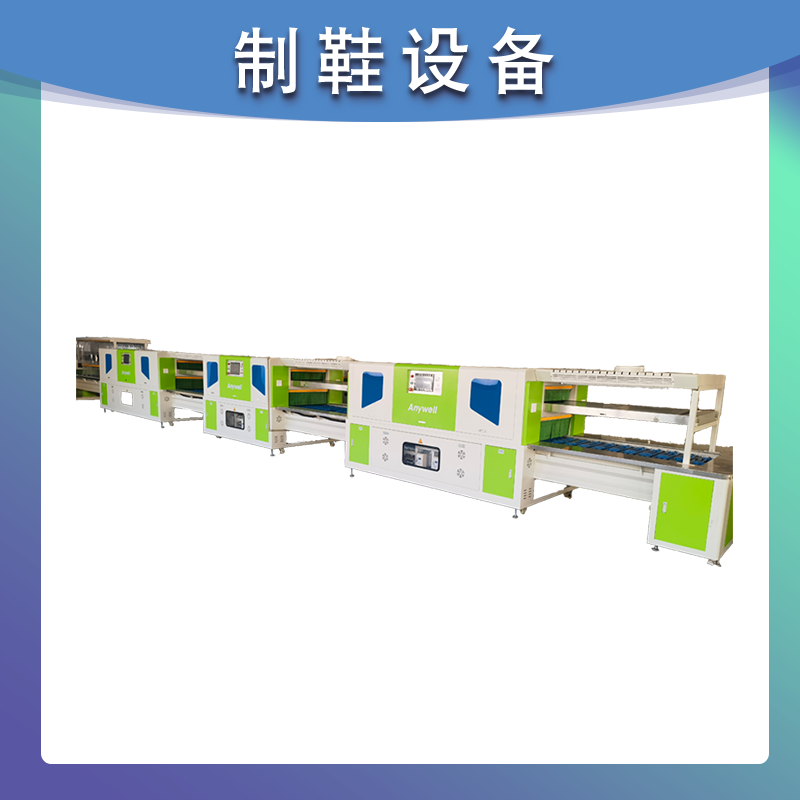

3. 灵活配置:可根据产品需求自由组合输送方式、工位数量及设备类型,适配不同生产规模与工艺要求。

4. 智能升级:集成PLC控制系统、传感器等,故障监测预警,降低人工依赖与管理成本。

5. 空间优化:模块化布局设计,合理规划生产空间,有效提升厂房利用率,节省场地资源。

Assembly Line Characteristics:

1. High-Efficiency Production:Multi-station collaborative operation enables continuous product processing, increasing production efficiency by over 50% and significantly shortening delivery cycles.

2. Precise Division of Labor:Standardized workflow with dedicated personnel for each step reduces human error and ensures consistent product quality.

3. Flexible Configuration:Customizable conveyor methods, station quantities, and equipment types to adapt to different production scales and process requirements.

4. Smart Upgrade: Integrated PLC control system and sensors enable fault monitoring and alerts, reducing reliance on labor and lowering management costs.

5. Space Optimization: Modular layout design maximizes factory space utilization, effectively saving site resources.