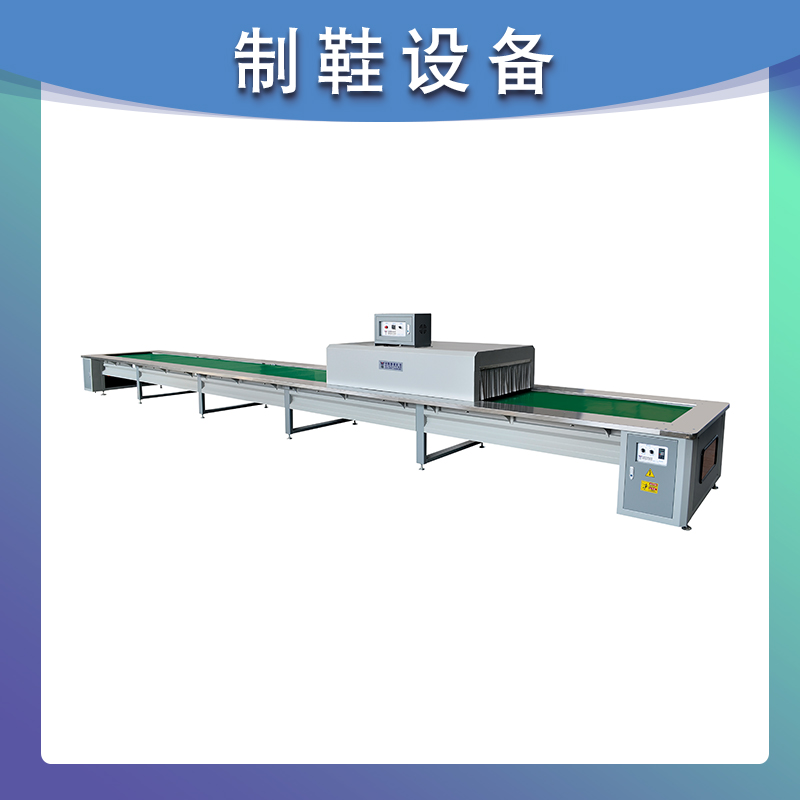

機器特點

加工生產大底省料5/10克(比老的生產工菱)

橡膠製品的排氟能力大大提升(降低橡膠製品排氧不良而造成的损失

色差,走色的問题從原頭解决

針對迷彩和橡膠大底高幫產品(原料生產每臺機省7到8人)现場生產實測單人單工位可日產多8到10只鞋底(厚計量片比)改水切後完全消除多餘的硬質酸锌,使後續的葉酸菜白從原頭解决

Features

Processing and production of large bottoms saves 5/10 grams of material (compared to older production processes)* The exhaust capacity of rubber products is greatly improved (reducing the losses caused by poor exhaust of rubber products)Solve color difference and color deviation problems from the beginning

For camouflage and rubber outsole high top products (raw material production saves 7 to 8 people per machine)e On site production testing shows that a single person and workstation can produce 8 to 10 more shoe soles per day (thickermeasuring plate ratio)

* After changing the water and cutting, completely eliminate excess hard zinc oxide, so that the subsequent folate leaf whiteningcan be solved from the original source